How productive is your factory?

Epirical data from, among others, Lean experts reveal that Danish companies on average use:

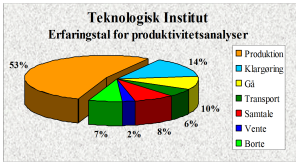

53 % of the time on production, the remaining 47% of the time is used on:

- Preperation

- Idle time

- Transportation

- Conversations

- Searching for things

– in other words: non-value-adding activities.

The time used in production is divided into:

Green time: Activities which, from the customers perspective, adds value to the product

Yellow time: Activities, which do not add value to the product, but are necessary. (Enabling processes)

Red time: Activities, which do not add value, and are not necessary (waste)

A productivity analysis is both a fast and effective method for:

- Breaking down how the costs for salaries are distributed

- Revealing potential optimizations within the factory

- Reducing the biggest causes for waste (Yellow + Red times)

- Involving the co-workers in identifying waste and listing potential solutions

How will your base line look line if your productivity increased with just 3-5%?